In the evolving landscape of architectural fabrication, software has become an indispensable tool in the production of millwork shop drawings. Traditionally, a labor-intensive and highly specialized process, shop drawing creation has been revolutionized by digital technologies that enhance precision, efficiency, and collaboration.

Modern millwork firms increasingly rely on advanced CAD (Computer-Aided Design) and BIM (Building Information Modeling) software to translate architectural intent into detailed fabrication-ready documents.

These tools not only streamline workflows but also reduce errors, improve material estimation, and ensure compliance with design standards and client expectations.

As the construction industry demands tighter timelines and higher levels of customization, the integration of software into millwork shop drawing production is no longer optional—it is essential.

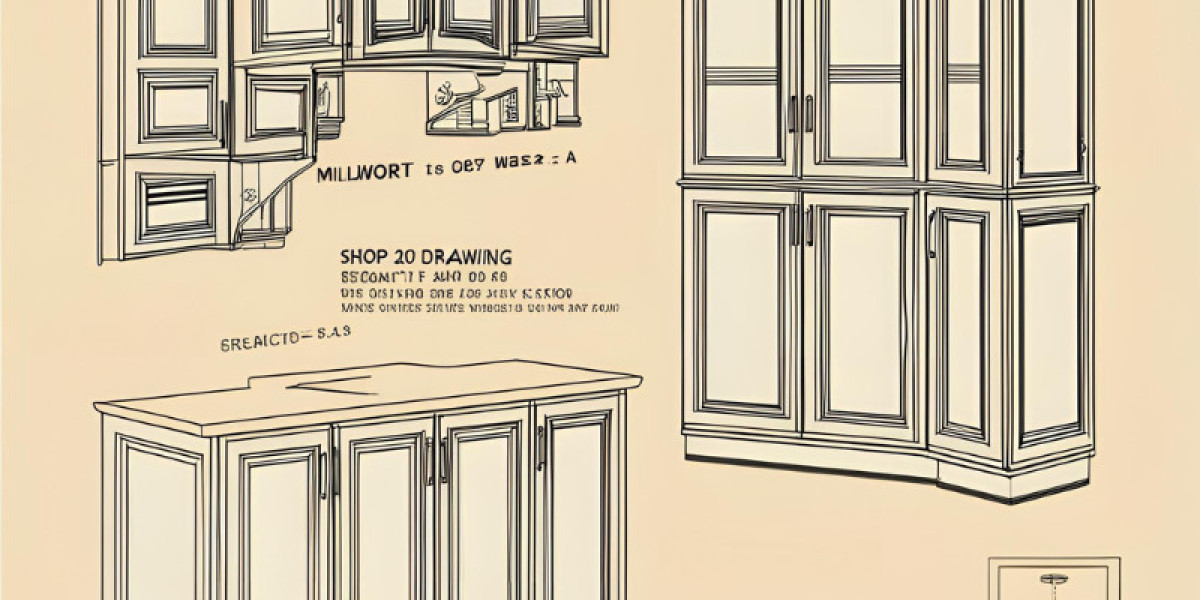

Overview of Millwork Shop Drawings

Millwork shop drawings are detailed plans used in construction and woodworking projects. They show how custom wood items like cabinets, doors, shelves, and moldings will be built and installed. These drawings are important because they help everyone understand what the final product will look like and how it will fit in the space.

Millwork shop drawings are usually made by a draftsman or designer. They are based on the architect's or interior designer’s original drawings. However, shop drawings include more details. For example, they show exact sizes, materials, finishes, and joinery methods. These details help the woodworkers in the shop build the product correctly.

The shop drawings are reviewed and approved by the architect, contractor, or client before the work begins. This review step helps catch mistakes early and makes sure the design matches the customer’s needs. Once approved, the drawings guide the production and installation of the woodwork.

Good millwork shop drawings include different views, such as front, side, and top views. They may also include 3D images, sections, and notes. Clear drawings save time and reduce errors during construction.

In short, millwork shop drawings are a key part of custom woodwork projects. They help turn ideas into real products by showing exactly how things will be made. Everyone involved in the project—designers, builders, and clients—relies on these drawings to make sure the job is done right.

Evolution from Manual Drafting to Digital Tools

In the past, all drawings and plans were made by hand. This was called manual drafting. Architects, engineers, and designers used pencils, rulers, and paper to create detailed drawings. It took a lot of time and skill to make accurate lines and measurements. Any mistake meant starting over or making corrections by hand, which was hard and slow.

Over time, technology began to change this process. In the 1960s and 1970s, the first digital drafting tools were developed. These tools became more popular in the 1980s and 1990s with the rise of computers. One of the most important tools was CAD, which stands for Computer-Aided Design. CAD software allowed people to create, change, and save drawings on a computer. It made work faster, easier, and more accurate.

Digital tools brought many benefits. Users could zoom in, use layers, and undo mistakes quickly. They could also copy parts of a drawing and use them again. Today, drafting is mostly done using digital software. Some common tools include AutoCAD, SketchUp, and Revit.

The shift from manual to digital drafting has changed how people work. It has improved speed, accuracy, and teamwork. Designers can now share files easily and work together from different locations.

Key Software Types Used in Millwork Drawing Production

In millwork drawing production, several types of software are used to design and create detailed drawings of woodwork, cabinetry, and other custom-built wooden structures. These software tools help designers, architects, and builders visualize, modify, and produce accurate construction plans.

CAD (Computer-Aided Design) Software: CAD software is the primary tool used for creating detailed 2D and 3D drawings of millwork projects. Programs like AutoCAD and SketchUp allow users to design precise plans for furniture, doors, windows, and other wooden elements. These tools help create detailed blueprints that are easy to scale, edit, and share with team members.

BIM (Building Information Modeling) Software: BIM tools like Revit offer more advanced features for millwork projects. They help integrate the millwork designs with the overall building structure, making it easier to see how woodwork fits into a larger project. BIM allows for better coordination among different design teams, improving accuracy and reducing errors.

Rendering Software: To give a more realistic view of the final product, rendering software like V-Ray or Lumion is used to create 3D visualizations. These programs allow users to add textures, lighting, and other effects, making the millwork design come to life before construction begins.

Estimating and Scheduling Software: Millwork projects often require precise cost and time estimates. Software like Cabinet Vision or 2020 Design helps with material calculations, cost estimation, and project scheduling, ensuring efficient production and delivery.

Benefits of Software in Millwork Drawing Production

Software has greatly improved the production of millwork drawings, offering several key benefits to professionals in the industry. First, it increases efficiency. With software tools, designers can quickly create accurate and detailed drawings, reducing the time needed for manual drafting. Tasks that would take hours, such as drawing intricate details, can now be done in minutes with the help of software.

Second, software allows for better precision. It minimizes human error, ensuring that the millwork drawings are more accurate and consistent. This is especially important when working with complex designs that require exact measurements. The software can automatically calculate dimensions and show potential issues, making it easier to catch mistakes before production begins.

Another benefit is the ability to easily make changes and revisions. If a design needs to be adjusted, it’s much faster and simpler with software. Designers can quickly modify parts of the drawing without starting over, improving flexibility and saving time during the design process.

Moreover, software can integrate with other tools and technologies, such as CNC machines, allowing for seamless communication between the design and manufacturing stages. This leads to smoother production processes and less room for errors when translating designs into physical products.

Finally, the use of software can enhance collaboration. Multiple team members can access and edit the same drawing simultaneously, improving teamwork and streamlining the review process.

The End Note

In conclusion, software has fundamentally transformed the production of millwork shop drawings, providing significant advantages in terms of efficiency, precision, flexibility, and collaboration.

The transition from manual drafting to digital tools like CAD, BIM, rendering, and estimating software has streamlined the design and fabrication process, reducing the time and effort required to create detailed, accurate plans.

These technologies not only minimize errors but also enable faster revisions, better coordination among teams, and more effective integration with manufacturing processes. As the demand for customized and high-quality millwork continues to grow, the role of software in ensuring precision and meeting tight deadlines becomes even more essential.

Ultimately, embracing these digital tools is crucial for modern millwork firms to stay competitive and meet the evolving needs of the construction industry.