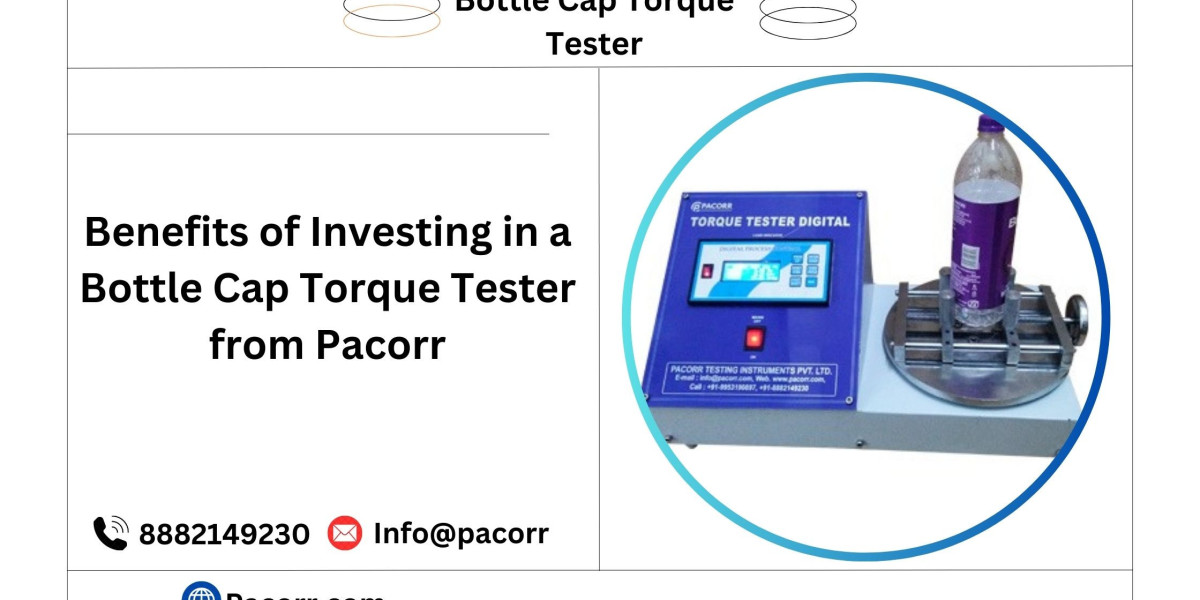

A Bottle Cap Torque Tester is a specialized instrument used to measure the force required to tighten or loosen a bottle cap, ensuring packaging integrity. At Pacorr.com, we provide high-precision, reliable, and industry-compliant torque tester designed to meet the needs of various industries.

What is a Bottle Cap Torque Tester?

A Bottle Cap Torque Tester is an essential tool used to measure the tightening and opening torque of bottle caps. This ensures:

✔ Leak-proof packaging – Prevents product spills and contamination.

✔ Consumer-friendly packaging – Caps are easy to open while maintaining a secure seal.

✔ Industry compliance – Ensures adherence to ISO, ASTM, and FDA packaging standards.

It is a crucial device for maintaining quality control and product reliability in manufacturing.

Why is Torque Testing Important?

? Prevents Leakage & Product Loss

Loose bottle caps can lead to spills, wastage, and damage, making torque testing essential for packaging integrity.

? Ensures Compliance with Standards

Industries like pharmaceuticals and beverages must follow strict regulatory guidelines to ensure consumer safety.

? Enhances Consumer Satisfaction

An ideal cap torque level ensures that bottles are secure yet easy to open, enhancing the user experience.

? Protects Product Shelf Life

Proper sealing prevents exposure to air, moisture, and contaminants, preserving the product’s freshness and longevity.

? Reduces Returns & Complaints

By ensuring consistent torque levels, manufacturers can minimize defects, reducing customer complaints and product recalls.

How Does a Bottle Cap Torque Tester Work?

A Bottle Cap Torque Tester works by measuring the rotational force needed to apply or remove a bottle cap. The process includes:

1️⃣ Securing the bottle – The bottle is placed in a fixture to prevent movement.

2️⃣ Applying torque – The cap is twisted in tightening (clockwise) or loosening (counterclockwise) directions.

3️⃣ Measuring torque – The instrument records the exact force required to open or close the cap.

4️⃣ Comparing with industry standards – Results are analyzed to ensure compliance with quality benchmarks.

Types of Bottle Cap Torque Testers

1. Digital Torque Testers

✔ Provides accurate digital readings.

✔ Allows data storage & transfer for quality control.

✔ Ideal for industries requiring high precision.

2. Manual Torque Testers

✔ Cost-effective and easy to use.

✔ Suitable for low-volume testing and laboratories.

✔ Requires operator skill for consistent results.

3. Motorized Torque Testers

✔ Automated operation for high-volume production.

✔ Reduces human errors and inconsistencies.

✔ Best for industries with strict quality standards.

4. Inline Torque Testers

✔ Integrated into production lines for real-time torque testing.

✔ Ensures consistent quality across all manufactured bottles.

✔ Used in mass production sectors like beverages and pharmaceuticals.

How to Choose the Right Bottle Cap Torque Tester?

When selecting a Bottle Cap Torque Tester, consider the following:

✅ Measurement Accuracy – Choose a tester with high precision digital readings.

✅ Torque Range Compatibility – Ensure it meets the specific torque requirements of your bottle caps.

✅ Ease of Operation – Look for a user-friendly interface for smooth operation.

✅ Data Logging & Analysis – Digital testers provide better tracking and reporting for quality control.

✅ Industry Standards Compliance – Ensure the tester meets ISO, ASTM, and FDA regulations.

Applications of Bottle Cap Torque Testers

1. Food & Beverage Industry

? Ensures bottles of water, soft drinks, juices, and dairy products are tightly sealed.

? Prevents leakage and contamination.

2. Pharmaceutical Industry

? Checks the torque of child-resistant caps on medicine bottles.

? Ensures tamper-proof packaging for safety compliance.

3. Cosmetic & Personal Care Industry

? Used for perfume, lotion, and shampoo bottles.

? Ensures premium product presentation and packaging integrity.

4. Chemical & Industrial Packaging

? Ensures chemical containers are properly sealed to prevent spills.

? Enhances safety in handling hazardous materials.

Why Choose Pacorr’s Bottle Cap Torque Tester?

At Pacorr.com, we manufacture high-quality torque testers designed for precision, efficiency, and durability. Our testers offer:

✅ High-Accuracy Readings – Ensuring reliable and repeatable results.

✅ Sturdy & Long-Lasting Design – Built for industrial environments.

✅ Easy-to-Use Interface – Simple controls for effortless operation.

✅ Customizable Features – Available in manual, digital, and motorized models.

✅ Global Compliance – Meets ISO, ASTM, and FDA standards.

Conclusion

A Bottle Cap Torque Testing is an essential tool for industries where secure packaging and quality control are priorities. By ensuring correct torque application, manufacturers can:

✔ Prevent product leaks and losses

✔ Enhance packaging consistency

✔ Improve customer experience

✔ Reduce complaints and recalls

✔ Meet regulatory standards

If you are looking for a reliable and high-precision Bottle Cap Torque Tester, Pacorr.com has the perfect solution for you.

? Visit Pacorr.com today to explore our range of advanced Bottle Cap Torque Testers! ?